| CNC | Precision CNC machining with a capacity of up to 1020 x 510 x 450 mm - Accuracy 0.003 mm | 3+2-axis CNC milling with a capacity of up to 6000 x 3500 x 1500 mm - Accuracy 0.03 mm | 3+1-axis CNC milling with a capacity of up to 4000 x 2000 x 3000 mm - Accuracy 0.03 mm | 5-axis simultaneous CNC milling with a capacity of up to 900 x 1050 x 850 mm - Accuracy 0.008 mm |

| Universal milling | 950 x 350 x 350 mm |

| Coordinated boring | 700 x 400 x 600 mm |

| Radial drill | R=1700 mm | Z=1250 mm |

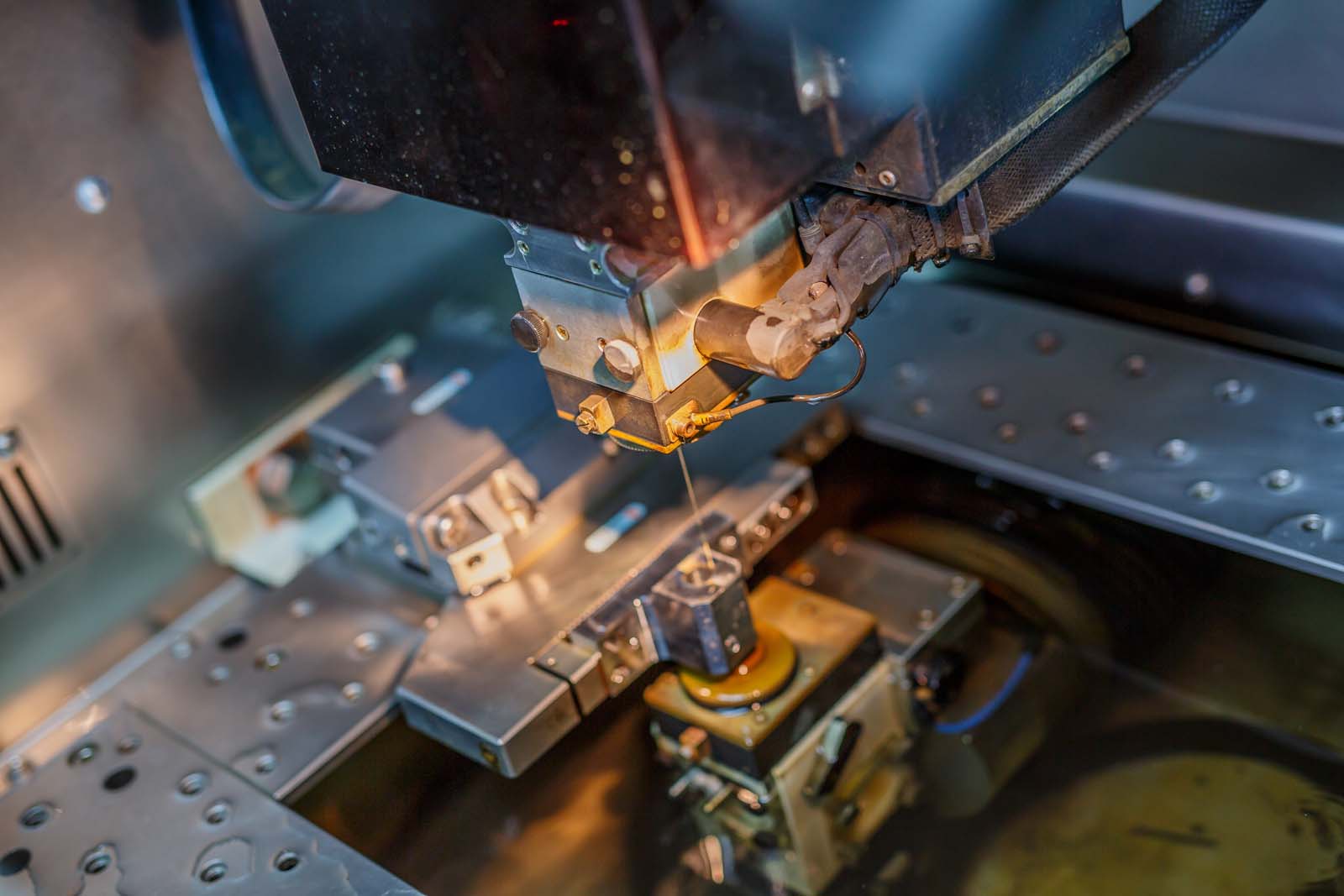

| CNC EDM | 600 x 450 x 400 mm - accuracy up to 0.003 mm - cutting possibility up to ± 10 ° |

| Electrode erosion | 1000 x 700 x 600 mm |

| Universal Grinding: | ø360 x 1500 mm | Tool diameter range: ø50 up to ø200 mm |

| External CNC Grinding: | Ø360 x 1000 mm |

| Internal Grinding: | Ø340 x 200 mm |

| Flat Grinding: | 2000 (1600) x 750 x 400 mm |

| Tools grinding | 150 x 150 x 200 mm |

| Gear grinding | Niles m=2-10 Ø500 x 150, number of teeth 12-100 |

| Furnace for case hardening, annealing and tempering | 600 x 1100 x 600 mm do 960 ˚C for case hardening, annealing and tempering |

| Flowing furnace for annealing and tempering | 400 x 150 mm do 850 ˚C |

| Plasma and carbo-nitriding | 1100 x 750 x 1200 mm |

| Tension removal | 3700 x 2250 x 1000 mm |

| Gear grinding | Pfauter m=1-8, Ømax.460, L=200, z=5-120 |

| Gear cutting | Felows m=1-8, L=50, z=10-174 |

| Conical gear cutting | Harbek modul 1 – 8.5 , D=20-500 |

| Broaching machine | power 7t , travel=1200 |

| Slotting machine | Travel l= 200 |

| Shot blasting with steel balls | 7000 x 4000 x 4000 mm |

| Glass bead blasting | 4000 x 3000 x 6000 mm |

| Sand blasting | 1000 x 700 x 800 mm |

| Black finishing | 500 x 750 x 850 mm |

| Chemical nickel plating | 380 x 550 x 850 mm |

| Anodizing line with possibility of Hard coating | 900 x 600 x 400 mm |

| Galvanizing line | 2300 x 550 x 1000 mm |

| Powder paint coating | 1350 x 4000 x 1600 mm |

| Wet painting | Drying chamber Up to 70 degrees. 7000 x 4000 x 3000 mm |

| Band and frame saw cutting | up to Ø500 mm |

| Steel plate flame cutting | According to template |

| Plate cutting with snips | 8 x 3000 mm |

| Plate cutting with circular snips | 6x Ø900 mm |

| CNC plasma or flame cutting | 2000 x 6000 mm - Steels up to 64 mm thickness, stainless steel and aluminum up to 35 mm, CNC flame cutting steel up to 120mm |

| CNC laser cutting | 6100 x 2500 mm table dimension Steel max 35mm, stainles steel max 35 mm, aluminum max 35 mm thickness, exactness ±0.05 mm |

| Water jet | 4000 x 2000 x 150 mm |

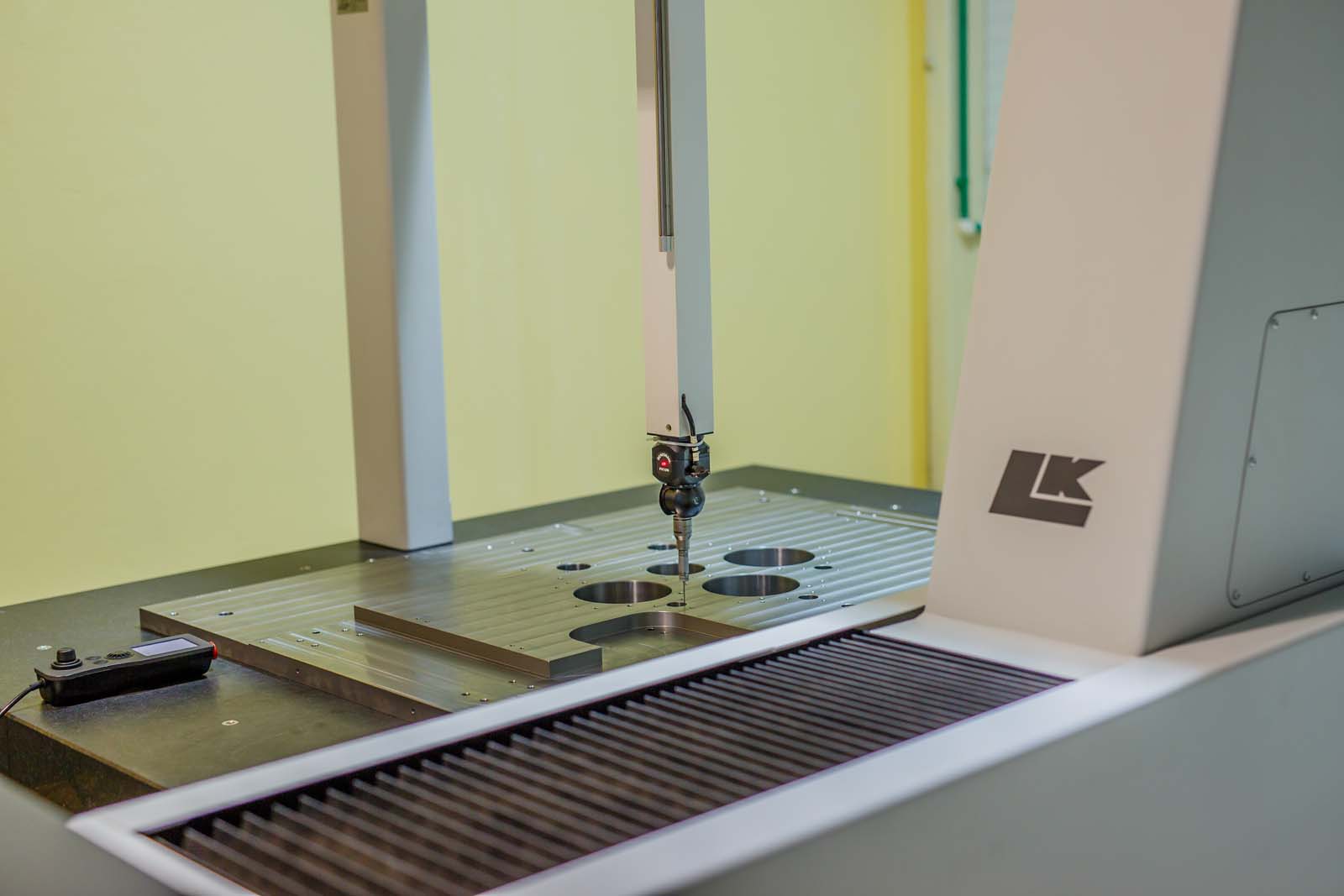

| Three coordinated CNC measuring | 1200 x 2400 x 800 mm ( Zeiss ) |

| Hardness tester | < 70 Hrc |

| Measuring arm | r1200mm |